The environmentally-friendly metal surface treatment series of biological agents developed and produced by the company use environmentally-friendly biological degreasing, rust removal, and magnetization film forming technology to make the product surface corrosion resistance, adhesion and impact resistance and other indicators can meet higher requirements . Because the process is environmentally friendly, stable, and easy to operate, it replaces the traditional processes of pickling, phosphating, silane and other multiple processes in metal surface treatment, and heavy pollution is not conducive to environmental protection and long-term development of enterprises.

SVJ—Biophysical and chemical color film agent

Using bio-physical methods to quickly form a dense physical and chemical color crystalline film on the metal surface, which has excellent corrosion resistance within a certain period of time, and the physical and chemical crystalline color film is firmly combined with the base metal, which can effectively change the physical and chemical properties of the metal surface. So that the surface will not rust before the anti-corrosion construction, and the surface bonding force of the paint film and the protective layer can be improved.

Main ingredient:It is composed of various special high-efficiency additives such as biological tannins, hydroxy acids, non-ionic surfactants, and biological chelating agents.

Operation method:The tank body requires PVC or FRP substrate

Processing method:Spray/soak

Open cylinder concentration: 5%

Operating temperature:Room temperature 15—45℃

PH: 2.5-3.5

Processing time: 5-15min

Drying temperature: 110-120℃(Hot air circulation drying)

Drying time: 10-15min

Product Features:

·After the workpiece is processed, a dense thin film golden yellow or colored crystalline film is formed, which has excellent corrosion resistance and enhances the adhesion of the coating film.

·The product is energy-saving and environmentally friendly, and does not contain heavy metals such as zinc, nickel, manganese, and chromium.

Scope of application:Prime treatment before coating of cold treatment, hot rolled steel and high and low carbon steel

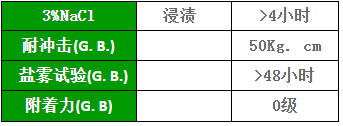

Film detection index:

Protective measures:

Operators need to wear protective masks, acid-resistant rain boots, gloves, and protective glasses. If you accidentally touch the skin or eyes, rinse with clean water in time. In severe cases, go to the hospital for treatment.

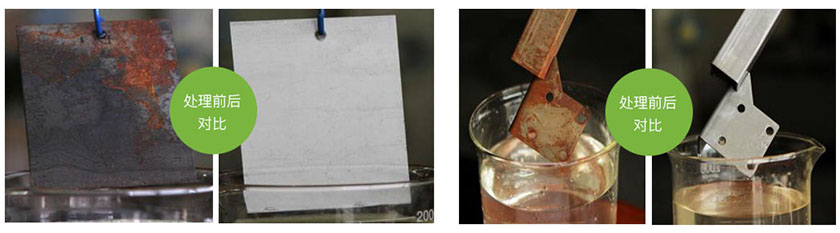

Film formation

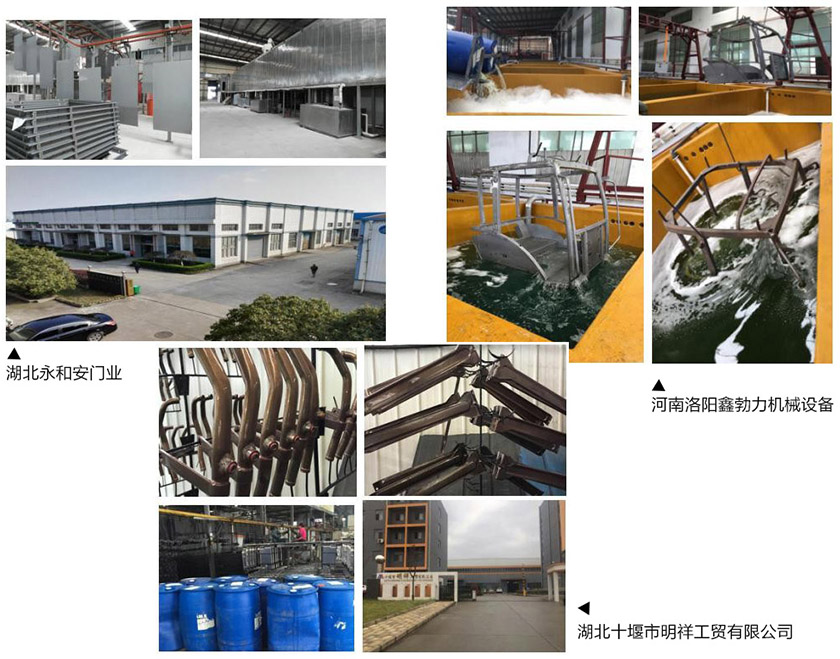

Use Cases

SVJ—Rust Remover

This product is composed of a variety of surfactants "AEO", high-efficiency additives, organic acids, etc., and a special corrosion inhibitor is added to the acid medium to have a comprehensive treatment function for oil and rust removal. It can effectively remove all kinds of oil stains, stains and rust layers at room temperature, and overcome the shortcomings of the traditional use of strong acid and alkali, high temperature degreasing and rust removal, and the danger of over-corrosion and hydrogen embrittlement. The use of oil rust cleaner can effectively prevent hydrogen embrittlement and over-corrosion, and improve the effect of oil removal and rust removal.

Processing flow:

SVJ—Rust Remover(soak)-Water wash①-Water wash②-Post-processing according to business needs

Processing area:30-40㎡/kg

How to use:Daily addition is carried out according to the processed rust area of the products produced every day.

Instructions:

The tank body requires PVC or FRP substrate

·Processing method: soak

·Operating temperature: normal temperature —30℃

·PH: ≈1

·Processing time:5-25min

Product Features:

·Thorough rust removal, effectively removing all kinds of plants, mineral oil stains, various oxide scales, welding stains and chemical pollutants, with fast speed and uniform surface brightness.

·Easy to operate, safe to use at room temperature, non-flammable and non-explosive.

·The liquid is acidic and has a light yellow appearance. It is stored for a long time without precipitation and turbidity.

Scope of application:

·Anti-rust oil, corrosive rust layer and oxide scale on the surface of ferrous metal.

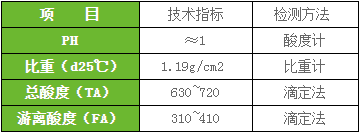

Technical parameter:

Protective measures:

Wear rubber gloves, rubber rain boots, and work clothes. Avoid long-term liquid contact with the skin, prevent the liquid from splashing into the eyes, and store it properly when not in use.